We offer an extensive product range of high-quality plastic packaging

APPLICATION AREAS OF OUR PRODUCTS

We offer an extensive product range from PE and PET bottles, PP jars, spray and dosing bottles, to trigger sprayers as well as canisters and have a very broad-based customer structure. Our high-quality packaging solutions have proved to be successful in the following application areas:

- Animal Farming & Care

- Automotive

- Child-resistant Packaging

- Cosmetics & Body Care

- Food Industry

- Home & Garden

- Professional

- UN Packaging for Dangerous Goods

Whether for the livestock farming or animal nutrition and care, like no other, plastic packaging must meet the sector correspondent requirements.

Whether for the livestock farming or animal nutrition and care, like no other, plastic packaging must meet the sector correspondent requirements.

Our extensive product range of plastic jars and bottles for pet food, animal care as well as stain and odour remover products complies with the quality standards and the EU-regulations. Chemical interactions between the product and the packaging are avoided. When developing customised packaging we rely on our profound industry knowledge.

The automotive industry imposes specific requirements on the plastic packaging for auxiliary, operating and care materials. These substances are, on the one hand, often aggressive and harmful to the environment and, on the other hand, have to be protected from outside influences. These substances put high requirements on the material, form as well as design of the packaging. In our broad product range you will certainly find the optimal solution for your packaging needs.

The automotive industry imposes specific requirements on the plastic packaging for auxiliary, operating and care materials. These substances are, on the one hand, often aggressive and harmful to the environment and, on the other hand, have to be protected from outside influences. These substances put high requirements on the material, form as well as design of the packaging. In our broad product range you will certainly find the optimal solution for your packaging needs.

Our packaging ensures that irritating, corrosive and hazardous to health substances are safely packaged and therefore do not adversely affect human health or the environment.

Moreover, our packaging protects your products against UV-light, evaporation, penetration of moisture or oxygen and many more. Apart from the protective function our packaging offers comfort and convenience in application: e.g. when dispensing and processing, storing and transporting your products.

Developing our products, we ensure that there is sufficient space for your imprint, label or marking. Our product range contains UN-certified packaging for dangerous goods with a tactile warning triangle symbol indicating dangerous substances and preparations. Upon request, we will furnish your plastic bottles with a transparent window strip to make the fill level visible.

In our printery we offer you various design possibilities. Moreover, we will gladly embellish your products with self-adhesive labels.

If you spray care or cleaning agents onto surfaces, we recommend our extensive range of sprayer bottles.

Our products are suitable for a broad range of applications – from handle bottles, which are practical to use, and dosing bottles for dosing of the contents to bottles with special closures e.g. child resistant and tamper-evident caps.

We produce round, flat and cylinder plastic bottles as standard solutions. For specific applications our specially shaped bottles are particularly suitable. Larger quantities you can easily fill in our canisters that come with the UN-certification for dangerous goods. For granulates, powdery, creamy or solid substances we offer jars with a screw cap. Our extensive product range meets the needs of the most demanding customers.

We will gladly develop a CI-conform packaging solution for you. Our modern machinery and our motivated and creative employees make it possible to find the optimal solution for each and every application.

In almost every household, on closer inspection, are different products to be found that may pose a danger to a child. These include for example household detergents, cleaning agents, drain cleaners, lamp oils, paints and lacquers etc.

Especially small children are at risk. Out of their thirst for knowledge and joy of discovery they learn about their surroundings through touch, sucking or chewing and therefore can swallow consumer chemicals that they find at home. In particular, colourful detergents and cleaning agents or bright paints and lacquers catch the child´s attention. Child-resistant packaging has to prevent small children from accessing those harmful household substances.

In the EU the CLP Regulation stipulates which substances and mixtures are to be packaged in a child-resistant way. Different standards specify the requirements and test methods for CRPs. For reclosable packages the international standard ISO 8317 and for non-reclosable DIN EN 14375 are Europe-wide recognized standards. Certification bodies accredited according to the DIN EN ISO/IEC 17065 are responsible for the testing and certification of child resistant packaging.

During the testing procedure up to 200 children aged between 42 and 51 months are asked to open a package. A child resistant package has to be impossible to open for at least 85 percent of the children. As the child-resistant packaging has also to be senior-friendly, the package is tested with a panel of adults aged between 50 and 70.

Child-resistant packaging is a rather simple way to protect small children at home and to prevent severe accidents. For that reason, our child-resistant packages, that minimize the risk as much as possible, are always in demand.

Cosmetics are very sensible products: water vapour and UV radiation, oxygen and CO2, contamination can not only influence the consistency and alter the appearance of the product but also lead to premature spoilage or drying-out. Suitable packaging must protect products against these harmful influences.

Cosmetics are very sensible products: water vapour and UV radiation, oxygen and CO2, contamination can not only influence the consistency and alter the appearance of the product but also lead to premature spoilage or drying-out. Suitable packaging must protect products against these harmful influences.

At the same time, the agency for consumer protection places high requirements on this type of packaging: the packaging must not contain any toxic substances and there should be no interactions between the packaging material and the product. Moreover, this type of packaging has to have sufficient space for the mandatory product and manufacturer information.

Other relevant criteria of the cosmetic packaging are aesthetic appearance and convenient handling. Plastic bottles and jars with a modern design, clever closures, dispenser pumps or trigger sprayers convince of the product quality more than the content itself filled in this packaging.

We offer you the optimal packaging for your cosmetic products – high-quality and decorative, printed and labelled:

Plastic bottles in various shapes suit e.g. for shower gels, body oils or shampoos.

- Dispensers can contain liquid soap or lotions.

Jars with screw caps are the optimal choice for cosmetic products with firm consistency e.g. creams and hair wax.

- Our customised solutions are tailored to the particular customer needs.

Product packaging for food industry is a very sensible topic. When transporting, storing and selling the packaging has a great influence on the product quality and shelf life. The following applies here: not only product damages and spoilage but also interactions of any kind between the packaging and the food products are must be avoided.

Product packaging for food industry is a very sensible topic. When transporting, storing and selling the packaging has a great influence on the product quality and shelf life. The following applies here: not only product damages and spoilage but also interactions of any kind between the packaging and the food products are must be avoided.

Furthermore, numerous national and international regulations and guidelines are to be adhered to as well as sufficient space for mandatory product information is to be provided.

The packaging functionality as well as aesthetics play an important promotional role. Our plastic jars, spray bottles and jerry cans are suitable for food storage. They protect products against negative environmental influences and help preserve their taste and consistency.

Our food packaging is light, functional, robust and can be easily labelled. Such competitive aspects as affordability, functionality and modern design are also worth mentioning.

The requirements for the modern plastic packaging are high. They must not only serve their purpose as functionally as possible but also show the product in an attractive light. The modern packaging has to be environmentally friendly and affordable at the same time. Another purpose of the packaging is to ensure safe transport of goods.

The requirements for the modern plastic packaging are high. They must not only serve their purpose as functionally as possible but also show the product in an attractive light. The modern packaging has to be environmentally friendly and affordable at the same time. Another purpose of the packaging is to ensure safe transport of goods.

Our plastic bottles and jars fulfil all of these requirements and for that reason, they are particularly suitable for a large number of household goods:

dosing bottles ensure precise gauging of liquid substances.

- dispensers release liquid products on your skin in a very hygienic way.

- grip-bottles ensure comfortable and safe handling of the product.

- sprayer bottles not only release the content evenly but also protect it from spoilage and evaporation.

- our jars with screw caps are suitable for granulates and pastes.

- our plastic canisters are ideal for larger quantities of liquid and semi-liquid products.

With all variety of our high-quality products they all have important attributes in common: our products are developed to the last detail; they are ergonomic; their high bearing load, robustness and long service life are impressive. It goes without saying that our products are recyclable.

Our plastic bottles, jars and canisters are usually utilized in the hotel business, cleaning services, glass cleaning, restaurants, industry and public institutions.

Our plastic bottles, jars and canisters are usually utilized in the hotel business, cleaning services, glass cleaning, restaurants, industry and public institutions.Thereby flammable, explosive or corrosive substances can be used. For these application areas we offer a wide product range of light, functional, ergonomic and break-proof plastic packaging in various volumes.

Our product range contains UN certified plastic packaging for liquid and pulverized dangerous goods. Should detergents or polishes be sprayed on the surfaces, our high-quality, ergonomic and robust plastic spray bottles can come in handy.

Various closure solutions from push down & turn closures to child resistant and tamper-evident closures – that can be tested and certified by the BAM in accordance with national and international standards like ADR – assure safety when handling potentially dangerous substances like corrosive cleaning agents.

With the help of our two-neck dosing bottles you can precisely gauge the desired amount.

Our grip bottles ensure comfortable usage even when handling larger quantities. When transporting and storing larger quantities our canisters plastic jerry cans can also come in handy.

Our plastic bottles with a window strip are particularly suitable in the PROFESSIONAL application area as the fill level of these bottles can be easily gauged.

Items or substances that may pose a danger to people or the environment are reffered to as “dangerous goods”. The packaging for dangerous goods has to meet particularly high requirements for those goods to be safely stored and shipped onshore, by sea and by air. According to the established design type tests plastic packaging for dangerous goods must withstand falls, squashing and aggressive chemicals. UN-certified dangerous goods packaging has to meet impermeability requirements as well as display particular properties under high and low temperatures.

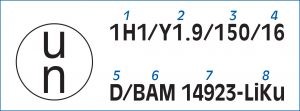

After being tested and analysed dangerous goods packaging receives an UN-approval number and a certificate containing information concerning material compatibility. Since 1991 BAM (Bundesanstalt für Materialforschung und -prüfung i.e. the Federal Institute for Materials Research and Testing) establishes the corresponding registrations. An UN-approval number informs about:

1. Type of the packaging and material

1 = container

H = made of plastic

1 = with a non-removable lid2. Packaging group and gross weight

Y = medium hazard

1.9 = Relative density being tested for the corresponding prototype3. Internal hydraulic test pressure in kpa (kilopascal)

150 kPa = 1 bar4. Year of manufacture

2016- 5. Country that issued the certificate

D = Deutschland i.e. Germany - 6. Institution that issued the certificate

BAM = Bundesamt für Materialforschung und -prüfung i.e. the Federal Institute for Materials Research and Testing - 7. Approval number

14923 = certificate No. 14923 issued by the BAM

8. Abbreviation of the manufacturer

LiKu = LiKu GmbH & Co. KG

We will gladly provide you with the corresponding certificates for our dangerous goods packaging upon request.

Our extensive product range provides a wide array of packaging solutions. If you cannot find what you are looking for, please contact us! Our experienced team will work out the optimal packaging solution for your application in collaboration with you.

Different branches have specific packaging requirements. Our know-how is applicable to the above-mentioned branches and has being optimised and tailored for over more than twenty years of the companies´ existence in order to meet those specific packaging requirements.